About LloydPans

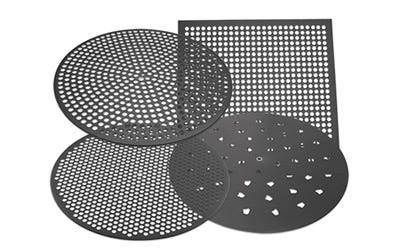

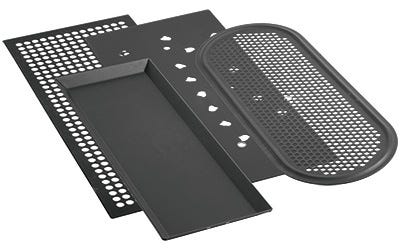

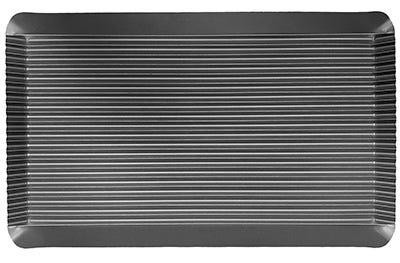

LloydPans, manufacturing pizza pans, bakeware and cookware since 1986.

Our company was founded on the simple premise of providing honest products and excellent service.

LloydPans.com

lloydpans.com is a website that is owned by Lloyd Industries, LLC, manufacturers of commercial baking solutions. LloydPans.com, live since 1999, is focused on selling baking solutions to pizza, bakery and foodservice customers.

All of our pans are manufactured in our 80,000 square foot plant in Spokane, WA including metal forming and spinning, hard coat anodizing and finishing.

Building Pizza Pans, Bakeware and Cookware in the USA

Commitment to Engineering for Excellence: Our products are engineered for performance and built to last. If something doesn't work, we will fix it or we won't sell it.

Customer-based innovation: We listen to our customers, and develop our products according to their needs and standards.

Creating the foundation of a better life through better food: Food cooked in our pans will retain the integrity of the chef's intentions. Our pans add no toxins, chemicals or other foreign substances.

Commitment to Our Customers

Customer Service: Our goal is to meet or exceed every customer's expectations through careful listening, attention to detail, sensitivity to needs and fulfillment of promises made. Our best ambassadors are our current customers.

Ongoing Innovation: We will always seek to improve our products and services through evaluation and continuous improvement methods. Ideas and innovations are proactively solicited from all our stakeholders, customers to engineers.

Product Value: Lloyd Pans are manufactured to meet the demands of service in commercial conditions. We strive to offer only the safest, most environmentally friendly, most useful and most reliable pans available. We will never compromise on quality or value to our customers.

Lloyd Industries is an ISO 9001:2015 certified facility.

ISO 9001:2015 is the internationally recognized Quality Management System (QMS) standard. Designed to be a powerful business improvement tool, ISO 9001 Quality Management certification is empowering LloydPans with a system for continuous improvement.

As a customer focused company, ISO 9001 is helping us improve customer relations, reduce manufacturing errors and deliver quality products. We want to ensure we are meeting each customer’s needs, inspiring trust in our products, our people and our business.

Key Personnel

Traci Rennaker, President and Chief Executive Officer

Traci brings more than 30 years of supervisory and executive experience in both retail and manufacturing environments to Lloyd Industries, LLC. She brings a background of expertise in both Lean Manufacturing and ISO 9001:2015 certification to the company. Traci combines project management and strategic planning skills to drive annual sales increases, reduce waste, and improve business and manufacturing processes. With superior customer service and leadership, Traci has been highly successful in aligning customer needs with corporate goals throughout her career.

Paul Lackey, Director of Operations

Paul is responsible for all aspects of the company’s production facility. He brings in excess of 30 years of field and shop experience, and has demonstrated talent in the mechanical and electrical areas of production as well as in R&D and data communications. His expertise spans such cross-functional areas as sourcing equipment and material, design and building custom production equipment, and providing for all maintenance needs of the company.

Bryan Williams, Controller

Bryan is a graduate of Whitworth University in Spokane, Washington and has more than 15 years of experience in accounting and financial reporting in the manufacturing industry. He worked in the assurance services department for one of the 10-largest Public Accounting Firms in the United States. Bryan is responsible for all accounting and financial aspects of LloydPans.

Paul Tiffany, Senior Designer

Paul is a graduate of Western Washington University with a bachelor’s degree in Industrial Technology. He has performed product design, machine design, plant design and layout, and lean manufacturing activities in many and varied environments. With an extensive background in materials and processes including forming and finishing metals, ceramics, and polymers he brings a wide range of cross-applicable skills to any design or manufacturing situation. He also is a ‘foodie’ with a strong understanding of the science of cooking and uses this to help Lloyd’s customers solve their food processing problems. Paul’s culinary talents lie in understanding the science and practice of food processing with an emphasis on baked goods, protein processing, and specialty ethnic recipes and seasonings.

Contact Lloyd Pans

Contact Lloyd Pans 800-748-6251

800-748-6251