Our customers have spoken, and we’re excited to announce our second anodization line in our Spokane Valley, Wash., location — where the LloydPans magic happens.

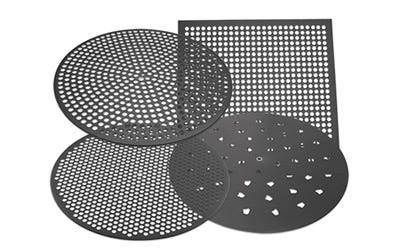

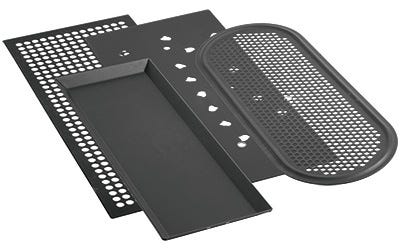

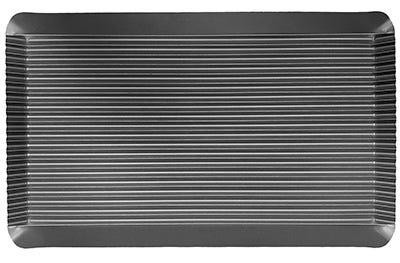

We do things a little differently at LloydPans, combining our anodizing process with water-based pan coatings, eliminating the reglazing process necessary for other pans. It’s a proprietary process that’s become so popular that we needed to ramp up efforts with a second line. The anodization process gives us not only a competitive advantage in performance, but also saves you, our customers, cost over the lifespan of your pans.

No reglazing equals cost savings over time, partly thanks to our revolutionary Silver-Kote and Dura-Kote permanent finishes. Unlike silicone, our durable permanent release coating will last through countless baking cycles without reglazing. The toxin-free finish we use is infused into the pan surface creating a durable baking platform that permanently stays with the pan. First, we start with an anodizing process, which fuses a ceramic-like hard shell directly onto our pans. Next, the pans are coated and baked in an industrial oven, which allows the coating to be absorbed into the pores of the anodized finish. Our coating is infused into the surface of the pan, so it cannot come off. It’s also a steam-proof finish, so there is no degradation of the finish from moisture.

Further, our coating is water-based, and our anodizing process demonstrates a comprehensive, proactive approach to responsible manufacturing. And, they are 100% PTFE-free.

Contact Lloyd Pans

Contact Lloyd Pans 800-748-6251

800-748-6251