Exploring Manufacturing Processes, Sustainability at LloydPans

When it comes to high-performing bakeware, LloydPans stands out for its commitment to engineering excellence. You may know Paul Tiffany, LloydPans’ director of product engineering, from our Ask Paul technical Q&A series. His expertise shapes products that excel in durability, heat retention, space efficiency and sustainability.

In this interview, Paul answers questions about the engineering strategies that make LloydPans a favorite among professional chefs and bakers. From unique materials to sustainable manufacturing processes, we’ll explore how LloydPans delivers industry-leading solutions for kitchens around the globe.

LloydPans are known for their exceptional durability. What materials and manufacturing techniques—that you can disclose—do you use to ensure LloydPans last longer than the competition?

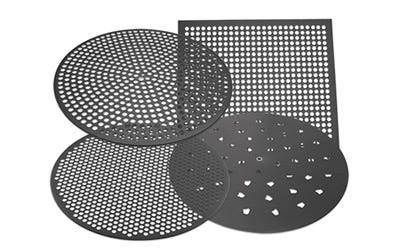

We use suitable gauges of aluminum for durability and heat transfer and then add permanent release finishes tuned to the specific uses of the pans. These are proprietary to us and unavailable from other suppliers.

How do LloydPans withstand the wear and tear of professional kitchens, where they see constant use and high heat?

Many of our pans are given a finish that starts by hard anodizing the aluminum, a metal utensil- safe surface of extraordinary abrasion resistance, followed by an infusion of a permanent release function—a permanent seasoning. This release is good to 700⁰F on an empty pan. With food being cooked there is no oven temperature limit if removed when the food’s cooked.

What kind of testing do you do to guarantee longevity and performance?

Raw materials are evaluated for compliance to our specification as well as having tight process controls on the work we do here.

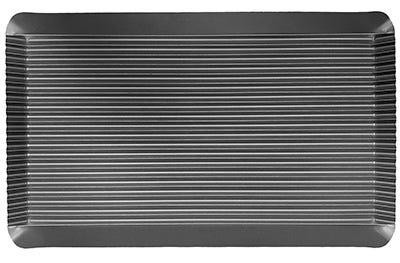

Heat retention is a major selling point. How does LloydPans ensure even heat distribution across the surface?

By the use of high conductivity aluminum and an appropriate choice of metal gauge.

How does better heat retention improve the cooking experience, particularly for bakers/pizzaiolos looking for consistent results?

Aluminum gives great heat transfer, and sometimes a heavy gauge is used for greater retention so you can get the best of both worlds yielding a more uniform color and bake through.

What role does material choice play in heat retention, and how does LloydPans differ from other cookware brands in this regard?

Through selection of material and gauge we can tailor the pan to meet the user’s needs based on their desired result. Seldom does one size fit all.

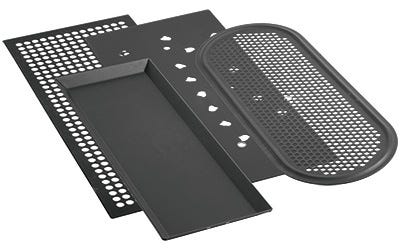

Space efficiency is something many customers look for when selecting cookware. How does LloydPans address this in their product designs?

Pans can be had in nesting versions so that they will fit inside one another for storage. We have self-stacking pans, which stack by partly fitting inside one another leaving a gap for proofing inside and the upper pan becomes a lid for the lower. We also have nesting pans, which use a separate lid to be able to proof but fit more completely inside each other. Both stack stably without slipping off while moving.

Sustainability is becoming more of a priority for consumers. How does LloydPans prioritize eco-friendliness in its manufacturing process?

We have always had an emphasis on durable, long-lasting products, made responsibly with a mind toward elimination of flimsy or single-use consumables. Our pan materials are recyclable, and all material remnants from manufacturing are recycled.

Certainly, our location in the Pacific Northwest with access to hydropower allows us to achieve efficiencies without the deleterious effects of other power sources. Our anodizing process rinse waters contain a desired material for the local water treatment facility to treat other company’s waste waters.

How does the durability of your pans contribute to their sustainability in the long run?

Certainly, a pan that will last 10+ years is a better investment and generates less waste. We are always looking to improve the performance and durability of our products to reduce replacement needs and waste. We do not view pans as consumables, but as important and durable tools to achieve the user’s goals.

Contact Lloyd Pans

Contact Lloyd Pans 800-748-6251

800-748-6251